|

The use of stainless steel for engineering applications has always led to something of an engineering paradox

| |

|

|

Dear Industry Expert,

The use of stainless steel for engineering applications has always led to something of an engineering paradox. While design engineers are happy with the strength and corrosion-resistance properties of steel, production engineers are less enamored with its work-hardening characteristics and lack of machinability. More... |

|

TOP STORY |

|

|

|

Automated die machining boosts capacity

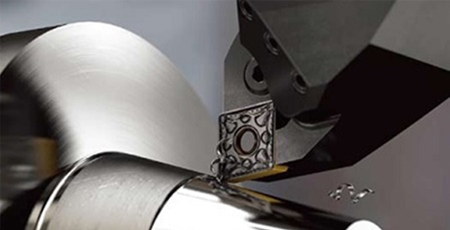

With the automotive sector continuing to specify stainless-steel components, the challenge for cutting-tool manufacturers is to deliver solutions that can provide ever-greater tool life and/or productivity to help machine shops succeed in an intensively competitive global marketplace. At Sandvik Coromant, there are high hopes for one such new solution. Machine shops turning austenitic and/or duplex stainless steel parts need an insert that is able to combat plastic deformation and wear to provide more parts per edge and therefore reduce cost per component. More... |

|

TECHNICAL HIGHLIGHT |

|

|

|

5-sided manufacturing of large workpieces

With its newest double column machining centre MCR-S, Okuma offers a machine tool that fulfils the demanding requirements of the automotive industry. When producing car bodies, manufacturers require press dies that are as precise as possible to achieve not only an extraordinary dimensional accuracy but also surfaces of the highest quality. As labour costs are on the rise, perfect surface quality needs to be achieved without manual polishing. More...

|

|

|

Multi-functional hard fine machining

In the Asia Pacific region, continuously variable transmissions (CVT) are valued for the efficient and economic vehicle transmissions they support. Automatic CVTs never interrupt traction and are considered a particularly efficient solution, one reason being that CVTs are very economical, especially within the lowest specific fuel consumption range. CVTs are used in both fuel-powered and partially electrically powered vehicles. More...

|

|

|

|

|

BorgWarner iCTA improves fuel economy

BorgWarner introduces its next generation of cam torque actuators – intelligent cam torque actuation (iCTA) – delivering better fuel economy and reduced emissions with its innovative technology. Leading the industry in the future of hydraulic cam phasing, iCTA blends the best attributes of cam torque actuation (CTA) and torsional assist (TA) phaser technologies. More...

|

|

|

Vario Cross Honing for precise gearing surfaces

By using a specially developed oscillation method during the honing process, “Vario Cross Honing” enables surface roughness to be reduced even further, resulting in another increase in the surface quality of geared components. This innovation, yet another benchmark in gearing machining from PRÄWEMA, allows gearing manufacturers to produce wear- and noise-reduced vehicle gearboxes with higher torque transmission. More...

|

|

|

Rotational torch sleeves for bevel, robotic cutting

Hypertherm is introducing three new torch sleeves for XPR plasma cutting torches and lead sets. The sleeves allow the torch and lead sets to remain axially fixed while the torch holding device rotates 360 degrees in either a clockwise or counter-clockwise direction. This capability greatly enhances torch lead life in high-flex applications. The new sleeves are ideal for bevel or 3D/robotic cutting applications. More...

|

|

|

Weland Solutions sets focus on automation

The market is moving towards standardized fully automated solutions, making setting focus on automation a natural step for us. Compact Dynamic is our first fully automated goods to man solution, which will respond to the demands of the industry and the rest of the world for efficiency and faster delivery times,” says Björn Karlsson at Weland Solutions. More...

|

|

|

|

|

|

|

|

|

|