|

The challenge faced by the metal industry is that it needs to meet all customer requirements despite the growing pressure on prices

|

|

|

|

Dear Industry Expert,

The challenge faced by the metal industry is that it needs to meet all customer requirements despite the growing pressure on prices. Digital networking of production could boost operational efficiency, but the industry still has a long way to go. |

|

TOP STORY |

|

|

|

Digital networking of production

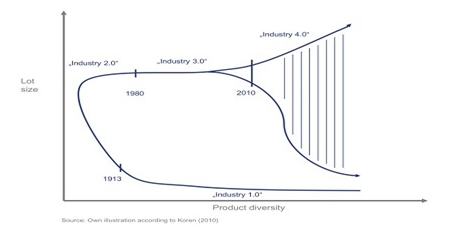

The digital era has kicked off two important trends: Firstly, there is a growth in larger companies that can produce efficiently, even smaller ranges of products, thanks to scaling effects. Secondly, there are smaller and more flexible companies that stand out because they can adapt their production systems individually, in some cases, for each customer. Within this continuum of potential value creation possibilities, companies have a wide range of options for using digitalised processes to adjust changing requirements. More... |

|

TECHNICAL HIGHLIGHT |

|

|

|

Perfect entry-level machine for 3D laser cutting

Over the last decade, local companies in South East Asia (SEA) increase the pace of innovation to survive and prosper in the face of customer demands for greater performance at a lower price and increased competition. Recently, TRUMPF launched a perfect introduction to 3D laser cutting at its Thailand Technology Center. Markus Lindemann explained the advantages of TruLaser Cell 5030 being an excellent value for money. More...

|

|

|

Two-in-one concept from WALTER

Tool manufacturers have been implementing WALTER's two-in-one concept in production for years now. But what is behind this concept which competitors have now even been trying to copy? From a production viewpoint, the two-in-one concept means that users can completely erode tools and also completely grind tools using one and the same machine. Both methods can be used on one and the same tool without the time-consuming step of switching to a second machine. More...

|

|

|

|

|

High-precision, flexible 5-axis grinding centre

The new PROFILE LINE from EWAG is a solution for efficient and flexible machining of indexable carbide inserts. The machine is built in close partnership with sister company Walter Maschinenbau GmbH and enhanced with Ewag AG's tooling and software expertise. This partnership has produced an extremely efficient grinding centre for advanced grinding of highly complex interchangeable insert geometries, including interfaces. More...

|

|

|

Inoue Kouzai raises productivity with Hypertherm

In today’s fiercely competitive manufacturing environment, the ability to maximize productivity while lowering costs is what sets companies apart from their competitors. Businesses are increasingly looking to the most cost-efficient solutions that also enable them to deliver the best quality products. Investing in cutting technologies that are capable of producing high-quality cut parts is one of the most crucial management decisions. More...

|

|

|

Efficient storage, sawing thanks to integration of intelligent robots

Automation, networking and robotics are rapidly gaining ground in metalworking – and in storage and sawing technology. Storage systems and sawing machines are increasingly being integrated into a uniformly controlled material flow in which all processes between incoming and outgoing goods are fully automated – from the storage of the long goods raw material to the dispatch of the palletized finished parts. More...

|

|

|

Efficient and flexible laser deposition welding

3D generating or additive manufacturing has the potential to revolutionise present design guidelines and manufacturing processes. The research company OSCAR PLT GmbH makes an important contribution to this change with its new development of the coaxial direct diode laser ProFocus. With a laser power of 1kW and six single laser beams which are arranged coaxially around the material feed, the ProFocus can be used flexibly for deposition welding with powder or wire. More...

|

|

|

|

|

|

|

|

|

|