|

Large output quantities, precise machining processes and massive cost pressure— transmission manufacturing requirements are demanding

|

|

|

|

Dear Industry Expert,

Large output quantities, precise machining processes and massive cost pressure— transmission manufacturing requirements are demanding, and will only become more demanding in the future as the automotive industry continues to evolve in this area. |

|

|

|

TOP STORY |

|

|

|

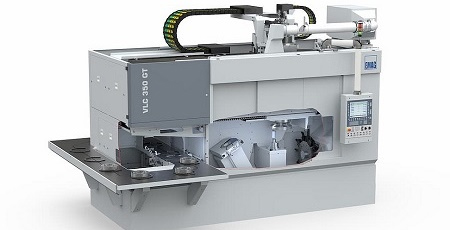

Perfect solution for future transmission and engine productions

What will the cars on the street look like in the future? For OEM’s and supply companies, this means that there will be a variety of conventional components, such as transmission gears, as well as new transmission components, produced in the future– in alternation and with a large amount of cost-pressure. The EMAG VLC 350 GT turning/grinding machine shows how this challenging task can be implemented, efficiently, in production. Different hard machining processes are performed on chucked components with a maximum diameter of up to 350 millimetres in succession and in a single clamping operation. Users benefit from a flexible solution with an excellent price-performance ratio.

More... |

|

TECHNICAL HIGHLIGHT |

|

|

|

Reduce your costs through digitalization

At this moment in time, machining companies are facing considerable challenges. Increasing pressure on costs due to the current crisis, pressure for further differentiation, a lack of transparency, fluctuations in incoming orders and a greater range of innovations require action to be taken and decisions to be made. Digital tool management is a first step to achieving transparency, improving processes and reducing costs. More...

|

|

|

SwissNano 7: floor space and efficiency as key concepts

The SwissNano 7 machine has proven its worth for many customers and it excels in the machining of parts for the medical and dental fields, as well as the electronics and micro-mechanics industries. It can optimize workpiece production in workshops. So, let’s take a brief look at how it manages to do so. This aspect is eye-catching: With its length of 3 meters and its 1-meter width, the SwissNano 7 is extremely compact, and even includes a high-pressure pump. More...

|

|

|

AI assistant from TRUMPF optimizes sorting process

TRUMPF has developed a solution that makes life easier for machine operators by helping them sort sheet metal parts from a laser cutting machine. The Sorting Guide uses an AI solution to identify which part the operator has removed from the machine and displays all the required information on screen. This includes information such as the next step in the process chain, for example. More...

|

|

|

|

|

Benefits of milling now also available for steel precision blanks

With this innovation, MN Coil Servicecenter is striving to achieve new standards of quality, greater product safety, and cost and time savings as result of less scrap for steel as well. Eliminating the need for costly investments in stamping tools will be particularly beneficial to manufacturers of vehicles with annual production volumes of less than 100,000 units. The milling process has also been tested on high-strength and ultra-high-strength cold-formed steel grades. More...

|

|

|

Kennametal introduces the eBore fine boring system

The eBore Fine Boring System consists of cutting units to cover a diameter range from 6 to 1020mm (0.236” to 40.157”) and an optional digital display that makes precision adjustments as simple as turning a screw—and costly mistakes a thing of the past. The fine boring system does away with the traditional count the graduations approach to boring and reduces costly mistakes. More...

|

|

|

CAD/CAM solution for flexible gear milling

The trend towards the production of flexible gears on 5-axis machining centres has been continuing for many years. WFL has recognized the trend and has already been able to inspire its customers worldwide with numerous installations. In cooperation with the Swiss company Euklid, the leading provider of advanced CAD/CAM solutions for 5-axis machining, WFL is now going one step further.More...

|

|

|

|

|

|

|

|

|

|