|

As the coronavirus (COVID-19) situation continues to evolve, technology is playing a critical role in allowing for remote working.

|

|

|

|

Dear Industry Expert,

Increasing pressure on costs due to the current crisis, pressure for further differentiation, a lack of transparency, fluctuations in incoming orders and a greater range of innovations require action to be taken and decisions to be made. |

|

|

|

TOP STORY |

|

|

|

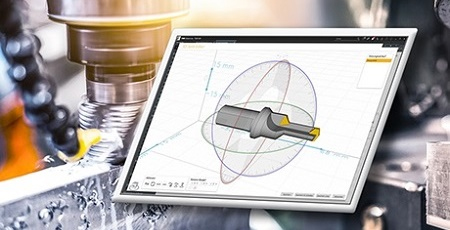

Reduce your costs through digitalization

Digital tool management is a first step to achieving transparency, improving processes and reducing costs. Having a central database with demand-oriented tool data gives companies a transparent tool inventory and, in conjunction with order-based tool planning, reduces tooling costs by up to 25%. Digital integration of tool data into the planning and production processes is the first step to a practical Industry 4.0 solution. By doing this, you can achieve a great deal with little effort. More... |

|

TECHNICAL HIGHLIGHT |

|

|

|

Navigating through spaces as narrow as 0.9 metres wide

Singapore’s leading autonomous mobile robot company SESTO Robotics has launched SESTO Magnus - a bi-directional, compact autonomous mobile robot able to carry loads up to 300kg. Having the highest payload rating in the compact class, SESTO Magnus is designed to automate material handling processes in manufacturing, commercial and healthcare industries, SESTO Magnus is able to autonomously travel through spaces as narrow as 0.9 metres wide.

More...

|

|

|

SKF launches Smart Supplier 4.0 Gen 2

Digitalising preventive maintenance for light industries in South East Asia and Australia are now more achievable than ever. Smart Supplier 4.0 Gen 2, a Digital Asset Condition Assessment programme launched by SKF Southeast Asia, helps users to work smarter, simpler, and in a more cost-effective way. It does all these by allowing users to detect possible causes of failures in their machines early on, so reparative measures could be taken before operations are impacted.

More...

|

|

|

|

|

Using AI to predict new materials with desired properties

Scientists in Japan have developed a machine learning approach that can predict the elements and manufacturing processes needed to obtain an aluminum alloy with specific, desired mechanical properties. The approach, published in the journal Science and Technology of Advanced Materials, could facilitate the discovery of new materials. Aluminum alloys are lightweight, energy-saving materials but also contain other elements. More...

|

|

|

Super Combi Compact: Smart system for beverage packaging

Two years after the introduction of the Super Combi to the industry for compact lines’ solutions, Sidel has now presented the next-generation solution Super Combi Compact that allows up to 30% footprint reduction compared to the previous model. It also presents an innovative product designed and engineered to deliver the lowest total costs of ownership (TCO) and production costs per square foot.

More...

|

|

|

DOMO and RPD to advance 3D printing

DOMO has formed a strategic partnership with Rapid Product Development GmbH, an Austrian leader in advanced 3D printing product development, rapid prototyping, and mechanical processing. The increased use of Selective Laser Sintering (SLS) in high-performance functional parts in automotive and other demanding market segments has created a need for plastic materials that are capable of bridging the gap between conventional injection molding and 3D printing. More...

|

|

|

Barrier-coated paperboard for smart packaging

The hunt for materials that can replace plastic is intense. Innovation work is being done on a global scale to find renewable alternatives to plastic so that humanity can reduce the huge impact on the environment from our use of plastic. Many solutions are being tried but we still have no material with all of plastic’s great advantages without its devastating disadvantages. More...

|

|

|

|

|

|

|

|

|

|