|

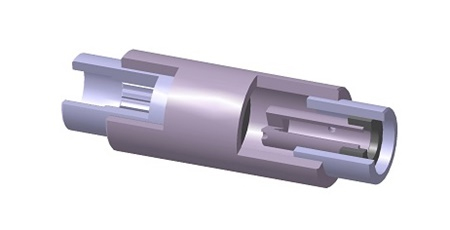

The core element of an electric powertrain is the motor, the main component of which is the rotor shaft

|

|

|

|

Dear Industry Expert,

The core element of an electric powertrain is the motor, the main component of which is the rotor shaft. By using tube instead of solid material, significantly less material is required in the manufacture of rotor shafts, which saves weight. |

|

TOP STORY |

|

|

|

Lightweight and safe e-mobility solutions from a single source

The trend toward electromobility is changing the demands on the production chain: Varying component quantities, diverse models, and rising demand for electric vehicles call for production capacities that are as flexible as possible. Production planners at suppliers and automotive manufacturers are therefore constantly evaluating their supply chains in order to either incorporate economically viable production steps into their production or outsource them. More... |

|

TECHNICAL HIGHLIGHT |

|

|

|

3D printing process for low alloy dual-phase steels in automotive applications

In an industry-first, GKN Additive successfully adapts and enhances DP600 like material, a widely used low alloy dual-phase steel in the automotive industry, for AM manufacturing, and enables diverse designs and applications in automotive and in other industrial sectors. The newly developed metal powder materials DPLA and FSLA meet similar requirements for mechanical properties, such as higher ultimate tensile strength and low yield strength. More...

|

|

|

Cobots lead the future of the global industrial robots market

Frost & Sullivan's finds that the global industrial robotics market will reach revenues of US$38.3 billion in 2024. Although the industry was curtailed by the COVID-19 pandemic and uncertainty in the automotive business, rising demand from other high-growth sectors is expected to propel it over the next five years. Asia-Pacific continues to dominate the global industrial robotics market with revenues estimated to top US$25.08 billion by 2024. More...

|

|

|

|

|

|

|

DENSO deploys Siemens’ software portfolio for digital transformation of automotive product design

The automotive industry is undergoing a once-in-a-century transformation. DENSO’s long-term effort to pursue value from both the vehicle and subsystem perspectives is a strategy to enhance growth and profitability. Research in Europe provided the opportunity for DENSO to have a direct discussion with Siemens regarding roll-out plans for Siemens’ MBD solutions which have a proven track record and are widely used by OEMs globally. More...

|

|

|

Efficiency package for aluminium and ISO N

Walter presents a range of products for machining aluminium, Al-Si alloys, magnesium and magnesium alloys, as well as for plastics and fibre composite materials. From Walter's perspective, these milling cutters offer the greatest potential in the general mechanical engineering sector and in the automotive industry, for instance when milling over small surfaces on aluminium components, as well as for ISO N components in the electronics industry.

More...

|

|

|

A smart shot blasting solution for integrated manufacturing lines

Increasing demand for electric vehicles forces the automobile manufacturers to expand their manufacturing capacities. Among others, this also includes production lines for stator carriers. The surface refinement of these components after the casting operation with a Rösler swing chamber blast machine RWK 6/12-2 must be achieved in very short cycle times within an interlinked manufacturing process.

More...

|

|

|

Lightweight solutions for the mobility of the future

Lightweight construction technologies are being used more and more frequently in automotive engineering. For electric vehicles in particular, it is important to compensate for the high dead weight of the batteries with lightweight elements. After all, the less mass that has to be accelerated, the less energy is lost. More...

|

|

|

|

|

|

|

|

|

|