|

For a long time, the generating grinding process was not suitable for the production of strongly asymmetrical

|

|

|

|

Dear Industry Expert,

For a long time, generating grinding process was not suitable for the production of strongly asymmetrical and undercut tooth geometry of cutting tools. To produce an asymmetrical cutting tooth with sharp cutting edges, specific process modifications had to be made. |

|

|

|

TOP STORY |

|

|

|

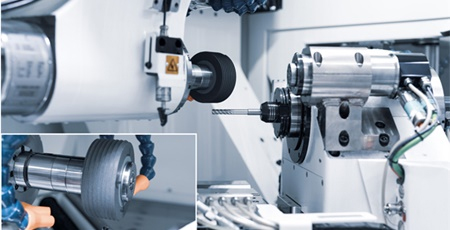

High productivity in manufacture of cutting tools

A new tool grinding technology process is currently being developed to reduce excessive non-productive times and increase productivity in tool production. It is based on work carried out by Dr.-Ing. Mirko Theuer of the IFW (Institute of Production Engineering and Machine Tools, Leibniz University of Hannover) for his dissertation. The resulting new generating grinding process holds enormous business and scientific potential. More... |

|

TECHNICAL HIGHLIGHT |

|

|

|

The next step to unmanned production

Sandvik Coromant explains why two new carbide inserts for steel turning — GC4415 and GC4425 — could hold the key to helping manufacturers balance the requirements of quality products and the pressures to operate with fewer workers on the shop floor, or in unmanned production scenarios. In this article, Rolf Olofsson details how the inserts could be significant when they are used with a digital platform of connected tools and software like Sandvik Coromant’s CoroPlus®. More...

|

|

|

MHI Machine Tool launches two new hobbing machines

Demand for mass production of high-precision gears is continuing to rise with the shift to electrification of vehicles. With the need for improvements in NVH and fuel efficiency, and the move toward low-cost manufacturing. MHI Machine Tool, with expertise in both gear machine tools and cutting tools, offers a full lineup of gear production machines, including these two new models. More...

|

|

|

|

|

Maximum process reliability meets maximum efficiency

A few years ago, dynamic milling was still a rarely used machining process. This is because it could not be carried out with the same level of efficiency that can be achieved today. Furthermore, it was limited to milling machines that could be controlled using CAD/CAM systems. This was state-of-the-art technology in the past, whereas nowadays CAD/CAM is the industry standard. More...

|

|

|

New 3D ipLaser cutting quotation suite halves customer response times

New cloud-based laser cutting quotation software from ipLaser typically more than halves the time and manual input required by laser cutting companies to prepare precise estimates for world industries using their services. The new technology differs from conventional 2D-based laser quotation technologies in that it can be fed full 3D schematics of a product and sift out precisely all the 2D sheet metal surfaces required to be cut by a laser workshop of any size and complexity. More...

|

|

|

|

|

Machine tool builder benefits from NSK motion control solutions

The Euromac XT sets the bar for innovation in the punching machine arena by being available in hydraulic, hybrid and electric variants. In each type, Euromac uses a different way of moving the main punching axis. In the electric version, for example, the technology holds its own patent. Here, acceleration of 90 m/s2 and stroke of sometimes less than 10mm, means that impact load is a constant issue. More...

|

|

|

|

|

|

|

|

|

|