|

A typical problem in tool grinding is so-called displacement. Process forces push away the tool being manufactured

|

|

|

|

Dear Industry Expert,

A typical problem in tool grinding is so-called displacement. Process forces push away the tool being manufactured, thereby reducing the potential accuracy levels. Find out how displacement during tool grinding can be compensated by intelligent process planning and the use of grinding spindles equipped with sensors. |

|

|

|

TOP STORY |

|

|

|

Dialog between top researchers and high-tech industry

Digitalization now plays a major role in many areas of grinding technology. The data-based manual optimization of grinding as an isolated process is currently in great demand. Industrial users are increasingly planning to use AI methods to predict the outcome of a process in order to reduce quality variations. AI tools can also be used for predictive maintenance of grinding machines. Digital twins can potentially make grinding processes even more assessable and certifiable by combining process data and scientific models.

More... |

|

TECHNICAL HIGHLIGHT |

|

|

|

The cutting edge of aerospace machining

For the aerospace industry, the cutting edge of parts machining goes far beyond having the latest CNC equipment and accessories. It also means engaging at the earliest stages of the process using the latest in design for manufacturing (DFM), simulation and process verification processes prior to cutting the first part. It is important to have flexibility and adaptability to make changes and scale production with the most precise tools throughout the process. More...

|

|

|

Roughing geometry for stainless steel

Paul Horn GmbH presents new innovations in the fields of carbide, coating and chip flow have enabled the development of a new generation of grades for turning steel. These parameters have been finely tuned to create the new grades for steel machining: BCP10T, BCP15T, BCP20T and BCP25T. The new Boehlerit steel grades offer high performance and machining reliability throughout the entire turning process. More...

|

|

|

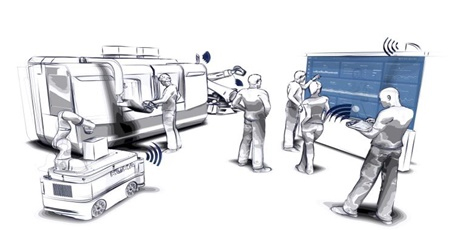

Hybrid manufacturing processes for increased competitiveness

Combining different manufacturing processes often pays dividends for manufacturing companies. This also applies to grinding and precision machining technologies. Significant increases in productivity can be achieved if modern automation and digitalization concepts are added, resulting in greater competitiveness. Large unit quantities, enormous cost pressure and precise production processes are among the major challenges facing gear manufacturers. More...

|

|

|

Security by Design now in machine tools

In order to protect existing machines, it is not enough simply to install a new operating system if the software provider no longer offers security updates for the old version, says Beck. The task is so challenging that an entirely new business field has developed in response. The focus must be on integrating security solutions into the development of a machine to ensure its resilience over its entire life cycle. More...

|

|

|

New CNC software simplifies usage of latest five-axis machine tools

The latest version of Flexium software from CNC specialist NUM includes an enhanced RTCP (Rotation Tool Centre Point) function with tool vector programming that significantly simplifies the usage of five-axis machine tools. As one of the original developers of RTCP, NUM continually enhances the function to meet the changing needs of machine builders and end-users. More...

|

|

|

FANUC brings automated CNC milling to education market

Schools, colleges, universities, independent training centres and OEM training facilities can all benefit from a new FANUC educational package that combines the company's machine tool and collaborative robot technologies. Developed in tandem with several leading industry partners, the ROBODRILL Educational Cell brings automated CNC milling to the training marketplace at a special cost-competitive price. More...

|

|

|

|

|

|

|

|

|

|